Blog

What Are Best Types of Printing For Pop-up Cards?

In pop-up card creation, choosing the right types of printing is crucial, blending artistic flair with precision. These cards, celebrated for their intricate designs and 3D elements, require specific printing methods for aesthetic and structural excellence.

This guide delves into various types of printing like thermal transfer, offset, silk screen, gravure, letterpress, UV, laser, and inkjet printing each offering unique benefits to pop-up card production. While not all methods suit pop-up cards, those that do enhance both visual and tactile aspects. We aim to provide insights into these methods, enriching your understanding and appreciation of this intricate art form.

How Many Types of Printing Techniques Are There?

In this section, we explore many types of printing methods, each with its unique strengths and applications. Whether it’s the precision of offset printing or the customizability of laser printing, understanding these techniques is essential for anyone looking to master the craft of pop-up card creation. Let’s delve into the specifics of each method:

Traditional Types of Printing:

- Letterpress Printing, a relief technique, involves inking raised letters or images and pressing them onto paper. This art form, often executed on antique cast iron presses over a century old, varies from crafting protest posters to fine books, with words meticulously typeset by hand, letter by letter.

- Thermal Transfer Printing transfers ink from a ribbon to the material, while direct thermal printing applies ink directly onto a substrate. Widely used for high barcode and alternative labeling, thermal transfer produces high-resolution, durable images suitable for various environments, distinguishing it from direct thermal methods.

- Screen Printing uses a mesh stencil to transfer ink onto a substrate, with a squeegee pressing ink through the mesh. Each color is printed separately for multi-colored designs. While traditionally silk was used, polyester and some other materials are also now common for the mesh, influencing the final design’s appearance.

- Gravure Printing, or rotogravure, is a high-speed, high-quality method ideal for long runs. It’s an intaglio form, like engraving, producing fine details, especially in CMYK printing where each ink color is applied by separate cylinders. Commonly used for packaging, wallpaper, and gift wrap, it’s also suitable for magazines, greeting cards, and large-scale advertising.

- Offset Printing transfers images from metal plates to rubber blankets, then onto media like paper, avoiding direct contact to extend plate life. Its flexible rubber adapts to various surfaces, including canvas and wood. Renowned for high, consistent quality, this method is versatile for small to large-scale printing jobs.

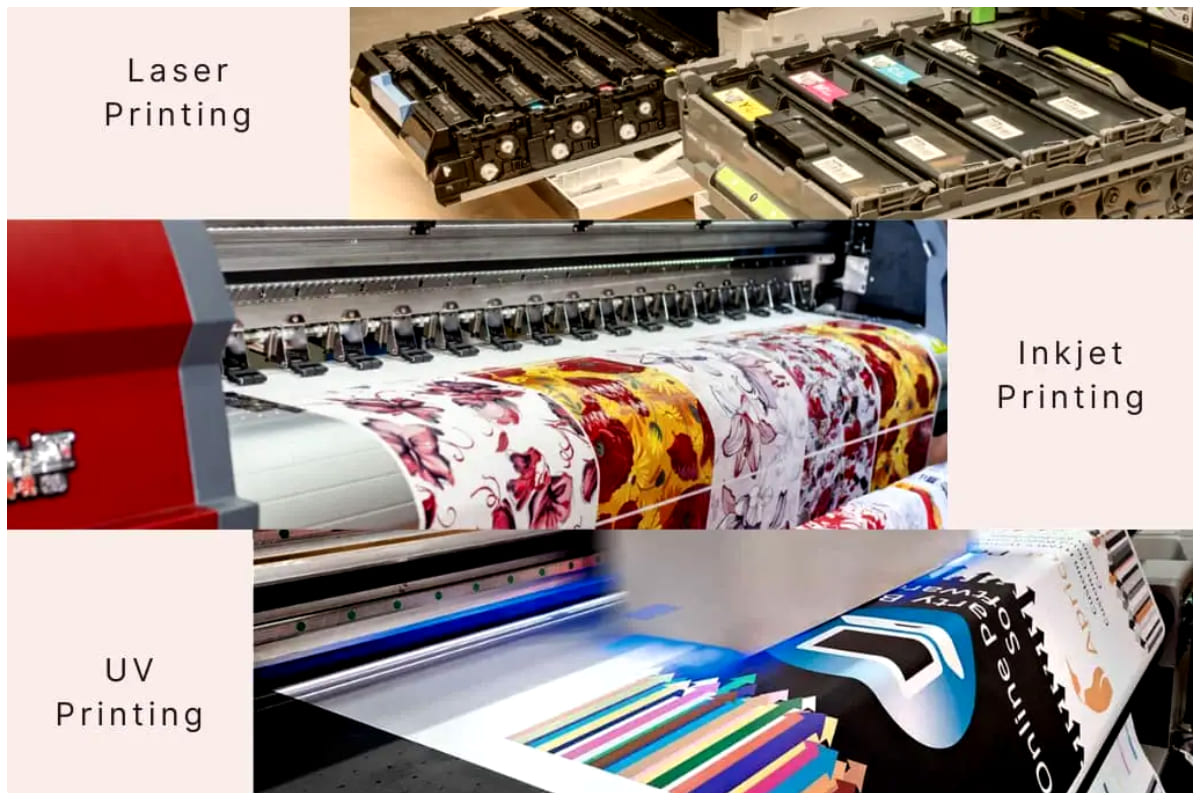

Modern Types of Printing:

- Laser Printing is an electrostatic digital process, that creates high-quality text and graphics. It uses a laser beam to charge a drum, forming an image that attracts toner. This image is then transferred and fused onto paper through heat. Unlike traditional xerography in analog photocopiers, laser printing directly forms the image on the drum.

- Inkjet Printing deploys minuscule ink droplets propelled through nozzles, and creates images or text on mediums like paper or canvas. Known for high-quality outputs, this method is versatile for both personal and professional applications, efficiently handling a range of printing tasks with precision.

- UV Printing, a digital method, uses ultraviolet light to instantly cure UV ink on various substrates, including paper, foam board, aluminum, or acrylic. As ink is applied, UV lights within the printer rapidly dry and adhere it to the material, making this process unique and versatile.

What Are the Best Types of Printing For Pop-up Cards?

In the diverse world of printing, certain techniques stand out for their unique capabilities, especially in the context of specialized projects like pop-up cards. Let’s dive deeper into four such types of printing: Laser, Offset, Inkjet, and Silk Screen Printing, each offering distinct advantages and challenges.

Laser printing

Laser printing, renowned for its efficiency in handling large volumes, is evolving to offer reduced performance costs. Their key advantage lies in the speed of the laser beam, significantly outpacing inkjet printers. This rapid printing capability, with even the slower models producing around 20 pages per minute, translates to heightened productivity and efficiency.

- Beyond speed, laser printers are celebrated for their reliability and durability. Unlike inkjet printers that use cartridges prone to drying and evaporation, laser printers employ toners. These toners are not only long-lasting, capable of printing between 15,000 to 60,000 pages but also contribute to the printer’s longevity with proper care.

- Laser printers come with higher initial costs, with the average price being nearly triple that of an inkjet printer. However, the cost-effectiveness becomes apparent in the long run. Toners, in comparison to ink cartridges, yield more prints per unit, making them economically advantageous if your intention is business-related.

- About print quality, laser printers produce sharp, precise, and vivid content thanks to laser technology that fuses toner directly onto paper, eliminating issues like smears and smudges. However, because of their ability to yield high-quality graphic images, the price per print is often higher than other types of printing. In summary, laser printing is the combination of speed, efficiency, durability, and quality that makes it a great choice for both high-volume and quality-precision printing needs.

Inkjet Printing

Inkjet Printing is popular among individuals and small businesses and offers an affordable solution for those with moderate printing needs. Their low initial cost makes them an attractive option, especially for smaller enterprises or home offices with limited printing demands. While the purchase price is budget-friendly, it’s important to consider the ongoing expenses of ink cartridges and maintenance, which can add up over time.

- In terms of performance, inkjet printers deliver high-quality prints but tend to lag in speed. They might not be the best fit for environments requiring rapid, high-volume printing. However, their compact and lightweight design is a significant advantage. These printers are not only quiet but also portable, making them ideal for those who need to move their printing setup for work or travel.

- Inkjet printers come in a range of sizes, from sleek, lightweight models to more robust, industrial versions. Some of the larger models can even match the printing speeds of laser printers. Despite the variation in size and cost, quality remains a consistent strength across the spectrum of inkjet printers.

- A common challenge with inkjet printers is ink clogging, where dried ink droplets obstruct the printer head, hindering printing capabilities. This issue, if not addressed properly, can lead to decreased functionality and potential damage to the machine. Regular maintenance is key to preventing such problems and ensuring the longevity and reliability of your inkjet printer.

Offset Printing

Offset Printing, a technique over a century old, continues to hold its ground in a world increasingly dominated by digital types of printing. This endurance stems from its unique advantages in certain scenarios where digital printing falls short.

- A primary benefit of offset printing is its aptitude for managing large-scale projects. It excels in producing vast quantities more cost-effectively than digital printing, a factor crucial in bulk orders. However, offset printing isn’t without its drawbacks. The process involves creating plates and transferring ink, which adds time and material costs. Consequently, for small-scale projects or those requiring quick turnaround, digital printing might be a more pragmatic choice.

- Offset printing also shines in technical customization. It offers a broader spectrum of options in terms of inks, materials, and finishes. Particularly noteworthy is its use of Pantone inks, enabling accurate color matching critical for projects like logo reproduction or precision-based imagery.

- In essence, offset printing, despite its age, remains a competitive player in the printing arena. Its suitability for large-scale, cost-effective print runs and its capacity for high customization and color accuracy make it a valuable option for specific printing needs. Yet, for smaller, time-sensitive projects, alternatives like digital printing could be more efficient. The choice between offset and digital printing hinges on the project’s scale, budget, and time constraints.

Screen Printing

Screen Printing, a venerable technique renowned for its durability, stands out in the traditional types of printing methods. This durability largely stems from the unique composition and thickness of inks used, such as Discharge, Plastisol, and water-based inks. These inks enable screen-printed designs, particularly on custom T-shirts, to endure significant stress without quality degradation.

- Despite its robustness, screen printing has limitations, particularly in color versatility. Each color requires a distinct screen, increasing both time and cost, especially for multi-colored designs. Additionally, the mesh screen application method limits fine detailing, potentially affecting designs with intricate patterns or small text.

- Conversely, screen printing is highly versatile and compatible with various substrates like fabric, wood, plastic, paper, and metal, provided the surface is flat. This adaptability makes it a go-to choice for diverse printing needs.

- Economically, screen printing is cost-effective for large orders. While initial setup costs are higher, the cost per unit decreases with volume, offering affordability for bulk printing.

- However, environmental impact is a concern. Screen printing can involve harmful chemicals and generate waste, factors important to consider in environmentally conscious decision-making. Overall, while screen printing offers durability and versatility, it requires careful consideration of its limitations and environmental implications.

In the end, each of these types of printing techniques offers specific benefits that can enhance the appeal and functionality of pop-up cards. The choice between laser, offset, inkjet, and silk screen printing should be guided by the project’s specific requirements, such as volume, detail, color needs, and turnaround time.

Your choice in types of printing is a balance of art and functionality, influencing everything from visual appeal to production efficiency. For enthusiasts and professionals alike, understanding these types of printing is key to transforming simple designs into captivating, three-dimensional masterpieces. As you select the right printing approach for your pop-up cards, remember it’s not just about the ink and paper; it’s about bringing a creative vision to life in the most impactful way.

🌐 Check out more at our website: https://kiricard.com/

✉️ Contact us: contact@kiricard.com

📞 Whatsapp: (+84) 931 57 6969

Christmas

Christmas Father’s Day

Father’s Day Valentine’s Day

Valentine’s Day Easter

Easter Thanksgiving

Thanksgiving Halloween

Halloween

Birthday

Birthday Wedding

Wedding Anniversary

Anniversary Graduation

Graduation Baby Shower

Baby Shower House Warming

House Warming

For Him

For Him For Her

For Her For Kids

For Kids

Floral

Floral Animals

Animals Trees

Trees Architecture

Architecture Vehicle

Vehicle LGBTQ+

LGBTQ+ Just Because

Just Because

Pop-up Box

Pop-up Box Pop-up Stand

Pop-up Stand